Accuracy is another important aspect in today’s world of robust businesses where speed and efficiency matter the most. A device that hardly receives its due credit in almost all retail and industrial applications is the label scale. From conveying the weight of the fruits and vegetables placed on them at supermarkets to the weight control in packing goods in the stores, a good label scale is essential. Rugtek’s Label Scale is one of the well-known companies that produce quality label scales. However, these scales are designed to be durative and long-lasting, and to help them remain that way, they require some maintenance.

Cleaning your label scale is very important to make sure that you get accurate readings and to also extend the durability of the scale. They are essential in many industries ranging from retailing, and manufacturing industries where accurate weights are essential to determine the pricing. Preventative measures by schedule maintenance are useful in preventing or reducing costly mistakes like needing a brand-new scale after a short time. Having a scale without maintenance is like having no scale at all. Regular label scale maintenance is necessary to extend the life and precision of these scales. Here in this blog, we are going to learn about some useful tutorials about label scale care tips on how to sustain your label scale along with examples.

Understanding the importance of label scale maintenance

To kick off the label-scale care tips, it is crucial to appreciate why it is an important factor in label-scale maintenance. Label scales are utilized in places where accuracy is mandatory. This may seem minor but even a slight variation creates a huge difference in the cost, stock, and even customers’ trust. Cleaning and other routine upkeep help to maintain your scale’s ability to work accurately, quickly, and consistently.

1. Regular Cleaning

Cleaning as a label scale maintenance practice is perhaps one of the most basic, and yet one of the most helpful ones. Salts and other substances from the air can settle on the scale and clog it thus leading to incorrect readings.

Example: Let’s take the case of a bakery firm that employs the use of a label scale to measure their ingredients. The scale might get its sensors affected if flour and sugar particles get in between. Spills Happen and Accidents are inevitable. If you do spill something on your scale, don’t panic! Immediately unplug the scale and wipe up the mess with a damp cloth. Let the scale dry completely before plugging it back in.

2. Calibration

Calibration involves bringing the scale to its proper zero point to get the correct reading. Over time, even the accurate scales may be set with a certain amount of divergence from the correct settings, which can cause an error in the calculation.

Label scale care tip: The manufacturer’s recommendations should be followed when it comes to the calibration. There are some types of scales where the point of calibration is incorporated while there are other types that may warrant professional help.

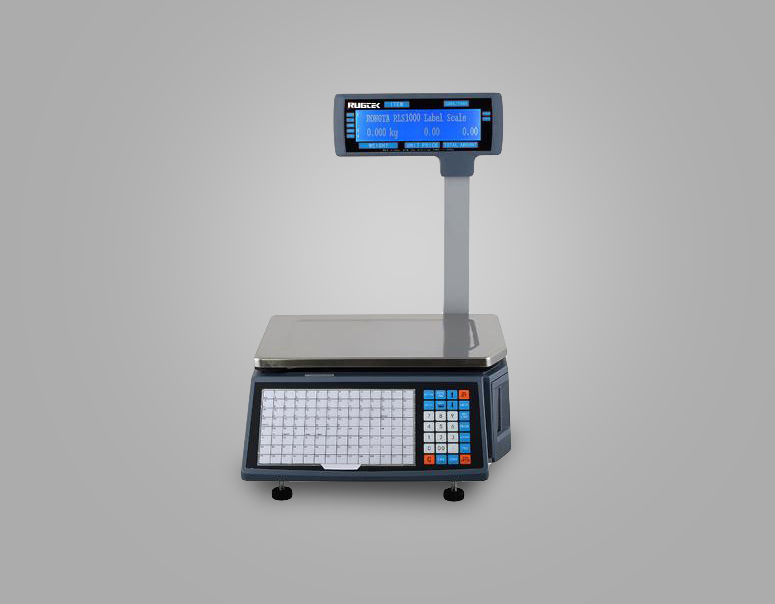

RLS- 1000H: Built to last

This one has the advantage of having a built-in system for the transfer of large quantities of product information (PLUs) through USB. This simplifies your operations, which means that you will not spend a lot of time on these tasks.

Spills happen. Dust happens. Buy label scale RLS-1000H, you don’t have to fret the same way you would anxiously do over the other products. The tough label scale is designed with the capabilities to tackle the harshest of conditions in endurance terms. For weather conditions it is heavily protected from water, moisture, and even insects thus it will keep on going no matter the challenge.

It is not simply a label scale, it’s a solid investment in efficiency and stylish appearance – the Rugtek RLS-1000H.

3. Environment control

The environment in which the scale is used can significantly impact its performance and longevity

- Mind the Temperature: Something that you have to be very careful with is that the scales are usually affected by weather hence an impact can lead to a wrong reading. Never leave your Rugtek under direct sun or near a heater; do not also place it near an air conditioning unit. It is preferable to have a low and cool environment as the humidity level is also important something that should also be kept low.

- Provide Ample Space: Buy label scales keeping in mind that the environment around the platform where packages are loaded and offloaded should be adequately spacious.

Example: It is recommended to install the RLS -1000p in the following zones: In a retailing environment, the equipment should be installed away from doors and windows since the temperature varies.

RLS 1000P: Perfect for retail

As it has an extended sleek design and shows consistency in performance, it is widely accepted among retail shops. From its construction, one can deduce that the RLS-1000P is all about the people who will be using it. The drawable printer seems to make the operation remarkably convenient no matter where it is.The RLS-1000P offers multiple barcode options, including 8-bit, 13-bit, and 18-bit. Buy label scales that ensure compatibility with a wide range of labeling requirements, whether you’re dealing with standard barcodes or more specific industry codes.

4. Inspection and testing

Why it matters: A periodic check of the facility reveals any problems that are still latent and can be solved or mitigated.

How to do it:

- Examine the scale for visible forms of wear such as cracks, and loose parts on any cable that is connected to the scale.

- It is recommended to check the scale with the weights of known values at regular intervals to ascertain proper functioning.

- Listen for unusual noises that might indicate mechanical issues.

RLS – 1000B

The RLS-1000B is endowed with a printer prototype that uses two motors in the printing section. This feature adds reliability to the unit and makes it possible to guarantee consumers high-quality label prints that are consistent and do not fade with time. It comes with a drawable printer module, therefore, routing through it is quite easy. Another feature of this design is that it provides easy access to the printer, some operations such as paper loading can be easily executed. No more stress with a large scale that is hard to manage – everything with the RLS-1000B is convenient and simple.

Conclusion

Through regular inspections and cleaning your scales can be kept in good condition. A label scale maintenance strategy can be formed that can help your scale remain the way they are over time. It is also important to choose a durable scale can save you money in the long run. Rugtek’s scales are known for their durability and are ensured to increase your sales. By following these label scale care tips, you can maximize the lifespan of your label scales and keep your operations running smoothly.